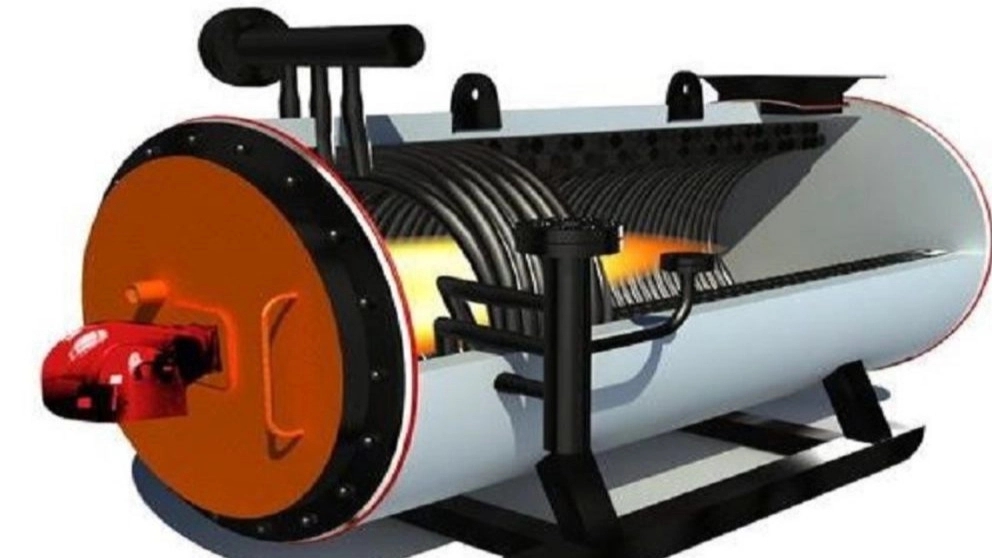

Hot Oil Boiler or Thermal Oil Heater is a device that transfers heat between the heat receiving fluid (special thermal oil) and the heat giving fluid (hot gases resulting from burner combustion) ) is used. In these boilers, by creating the necessary heat transfer surface, the heat of the gases from the combustion of the burner is transferred to the circulating thermal oil and increases its temperature. Using a hot oil boiler, high temperature can be achieved in Low working pressure is possible. The working temperature is usually between 150 and 300 degrees Celsius. (Higher working temperatures require the use of special materials, equipment and thermal oil and are not recommended due to the risks and higher depreciation of the system.)

Types of hot oil heaters

According to the capacity and design specifications, hot oil boilers are produced horizontally or vertically, both of which have their own advantages and disadvantages. Vertical boilers are usually used in low capacities or due to space limitations. Also, horizontal boilers usually have higher efficiency.

The most important application:

It is one of the most important boilers in various industries, which is used for indirect heating.

Heating is used at temperatures above 200 degrees Celsius. The most common applications of hot oil boilers are in chemical industries and bitumen and asphalt industries. Hot oil boilers are used in chemical industries and inside reactors to transfer heat to carry out chemical reactions and perform various stages of production processes. .

Advantages of hot oil system over steam boiler

1. Operation in low pressure conditions

2. Creating high temperature and of course the need for a lower thermal surface

3. No possibility of corrosion (due to the chemical structure)

4. No freezing during The device is turned off

5. No sediment clogging and naturally increasing the heat transfer efficiency

6. No need for equipment to refine and soften the oil

7. No need for chemical dosing systems to improve the chemical quality of the oil

8. Absence of thermal losses due to condensation and steam flash

10. Absence of steam traps

11. No possibility of explosion due to compression of compressed gases

12. No need for de-irritor and tank Condensation

13. No need for Bludan

14. No need for a vacuum breaker

15. Ease of management and less need for maintenance